$6 million awarded to prepare site for Millinocket Salmon farm

FOR IMMEDIATE RELEASE

MILLINOCKET, ME. 5/20/2024 – A $5 million EPA grant has been awarded to remediate and prepare the project site for the construction of Katahdin Salmon’s RAS facility. The grant was awarded to our development partner Our Katahdin for the remediation of the project site in collaboration with Katahdin Salmon. This grant comes in addition to $1 million in funding from the DECD in Maine for the same purpose.

“We are delighted to announce that we have been awarded a $5 million grant from the U.S. Environmental Protection Agency (EPA). The grant will play a crucial role in remediating 26 acres of the former mill site’s wastewater lagoon. This EPA-funded project will clear the way for Great Northern Salmon’s (formerly Katahdin Salmon) aquaculture project which has secured major project permits and is scheduled to begin construction in 2025” said Sean DeWitt, president of Our Katahdin.

“We are grateful for the support of the EPA, our federal delegation, and the many local and state organizations that have supported the clean-up and infrastructure improvements to the former mill site. These investments are laying the foundation for significant job creation and a better economic future for the Katahdin region,” he says.

These federal and state contributions reduce the overall CAPEX for the company and enable the company to start construction with a fully prepared and excavated site, reducing the construction cost and timeline. The construction schedule advantage is estimated to be six months.

“Being selected for a substantial grant like this by the EPA speaks to the high-quality work that our development partner “Our Katahdin” has put into developing the former paper mill site and also the great potential for Katahdin Salmon to repurpose the site”, says Marianne Naess, CEO of Katahdin Salmon.

An RFP for remediation was issued in April and contractors from across the country have shown interest in the project. The project will be managed by Sevee & Maher Engineering. The contractor is expected to be selected within the next few months with a remediation starting later this summer. The primary work involves decanting the lagoon, removing old infrastructure, and in-situ handling of the sludge deposits.

Katahdin Salmon changes name to Great Northern Salmon

Katahdin Salmon is now entering a new phase and has decided to rebrand the company. The new company name is “Great Northern Salmon”.

The Millinocket facility will be located on the 1400-acre property that belonged to the Great Northern Paper Company which permanently closed in 2008. When the Millinocket Mill opened in 1900, it was the world´s largest paper mill. It was the first paper mill to have an on-site hydro generation and distribution facility. The Great Northern Paper Mill was the cornerstone of the community and made the town one of Maine’s most thriving communities.

“Katahdin Salmon has been a good name for the initial development phases in Maine. Now that the company is entering into a new phase, it is the right time to transition to a name that reflects the developments of the company and the way forward but that still ties the company to the local community,” says Marianne Naess, CEO of Great Northern Salmon.

- The company is focused on developing the first site in Millinocket. Still, the new brand will be scalable to future locations and reflects our ambition to expand to future locations in North America.

- The brand “Great Northern Salmon” represents the company´s vision: producing high-quality salmon in areas with access to plenty of clean and cold water in the Northern USA.

- The new brand reflects the ties to the community and its history and at the same time represents our future ambitions and direction.

The new company logo will keep the same logo element: fish swimming in a round tank. The colors are dark blue representing the clean & cold water and the salmon color representing our products.

The picture below shows Millinocket with the remaining parts of the paper mill in the foreground and Mount Katahdin in the background. Great Northern Salmon´s facility is located to the right of the river. The historical paper mill only occupied a small portion of the property.

Photo Credit: Designlab

The map below shows the former Great Northern Paper Company´s site (One North) now being developed by “Our Katahdin.”

Credit: One North

Nofitech selected as RAS vendor for Great Northern Salmon´s Millinocket farm.

After a thorough review of options for RAS design vendors, Great Northern Salmon is pleased to announce that we have selected Nofitech as the designer for the facility in Maine.

Great Northern Salmon’s experienced production team has a clear vision for our future RAS design and functionality, and Nofitech´s approach was the best fit technically, commercially, and culturally.

“It became clear as soon as we started exploring future collaboration that we see things the same way and that Nofitech has a design that is compatible with our bioplan. Nofitech´s reputation for delivering on expectations for cost, performance, and schedule, proven through its repeat business with several customers, was also an important factor in the decision” says Dean Guest, Head of RAS Technology.

“We would like to thank Great Northern Salmon for the trust and are proud to have been chosen as the RAS vendor for their project in Maine. This marks the start of a long-term partnership with Great Northern Salmon, based on shared values, understanding, and objectives”, says Robert Hundstad, CEO of Nofitech.

Detailed design is scheduled to start this summer.

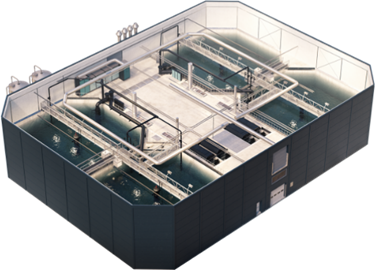

Picture and description of Nofitech´s RAS design

Cost-efficient and compact

The combination of compact design and extensive use of standardized prefabricated units provides a lower total cost than similar facilities. The compact patented structure provides short pipelines, less footprint and is designed to prevent the accumulation of sediments. Construction and design are developed for production with freshwater and production in the most demanding environments with seawater.